Graphene has attracted increasing interest in both theoretical and experimental communities due to excellent physical properties and potential applications, such as electronics, energy storage, thermal management, functional composite materials, etc. High-yield production of few-layer graphene (FLG) is important for the scalable synthesis and industrial applications of graphene. Electrochemical exfoliation provides alternative approaches to prepare graphene sheets. However, there exist several issues in terms of yield and quality, which hinders the application of FLG prepared by electrochemical exfoliation. Additionally, isolated graphene sheet brings about problems in some practical applications for its small scale. Recently, it can be effectively resolved by the assembly of graphene sheets into three-dimension (3D) macroscopic structures, which contains a great quantity of small voids and openings. Thus, it is significant to exploit low-cost and simple techniques to prepare graphene materials with high yield and fabricate 3D graphene macroscopic film, foam and bulk materials for the promising applications of graphene.

Recently, Prof. Liwei Liu group at Key Laboratory of Nanodevices and Applications, Suzhou Institute of Nano-Tech and Nano-Bionics (SINANO), Chinese Academy of Sciences (CAS), has successfully developed a facile and high-yield method to produce few-layer graphene (FLG) by electrochemical intercalation exfoliation (EIE) of expanded graphite in sulfuric acid electrolyte. Stage-1 H2SO4-graphite intercalation compound is used as a key intermediate in EIE to realize the efficient exfoliation. These electrochemically exfoliated FLG flakes are integrated into several kinds of macroscopic graphene structures. Flexible and freestanding graphene papers made of the FLG flakes retain excellent conductivities (~24,500 S/m and 150 S/m). 3D graphene foams with light weight are fabricated from the FLG flakes by the use of Ni foams as self-sacrifice templates. Furthermore, we fabricated the electrical double layer capacitor (EDLC) by using the 3D graphene/Ni foam without any binders as electrodes. The symmetrical EDLC in aqueous electrolyte shows nearly ideal capacitive behaviors and provides high specific capacitance of 113.2 F/g at a current density of 0.5 A/g, retaining 90% capacitance after 1000 cycles. The current work has an important influence on the studies of both the fabrication of 3D grpahene macroscopic materials and the power storage application of graphene. In addition, graphene paper and foam fabricated by this method have potential applications in thermal interface material, electromagnetic shielding, biological medicine and so on. This work has been published on Small10 (7),1421(2014).

This work was supported by National Natural Science Foundation of China, and Ministry of National Science and Technology Projects of China. The project also got assistance from the Nanofabrication Facility and Platform of Characterization & Test of SINANO.

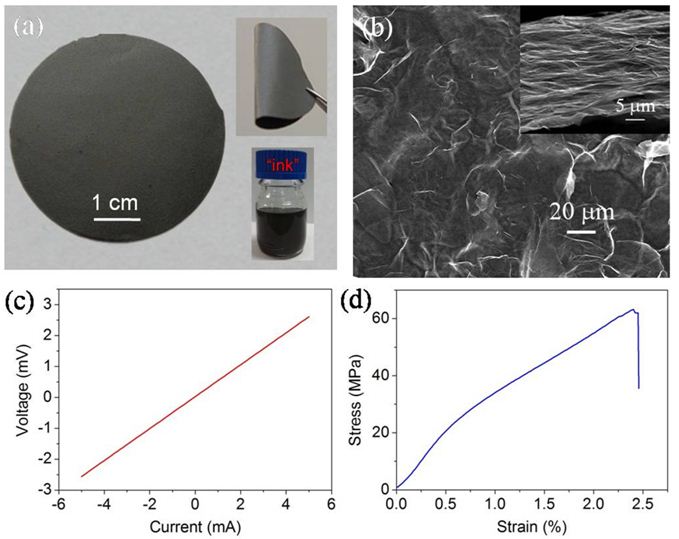

Figure 1. a) Photograph of free-standing graphene paper (GP). Inset is graphene “ink” containing about 30 mg of FLG in 60 mL of ethanol. Free-standing GP is prepared by vacuum filtration of the graphene “ink”, followed by peeling off the membrane filter. The prepared GP shows a highly flexible and mechanically robust nature. b) SEM image of free-standing GP observed from the top view. Inset is the cross-section observation of GP. c) Voltage-current curve of our GP measured by a four-point probe technique. The thickness of the GP is 18 μm. d) Stress-strain curve of our GP. (Image By SINANO)

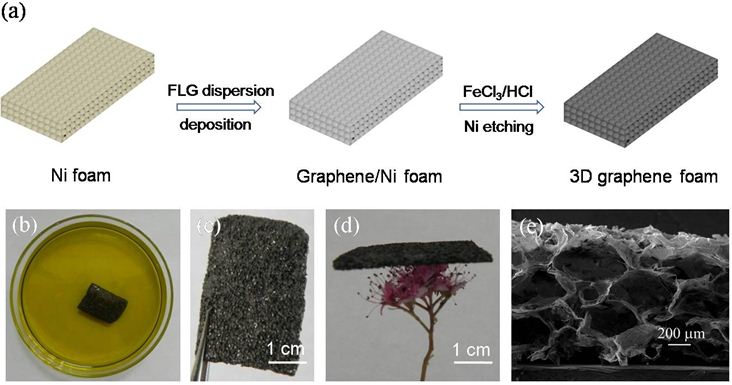

Figure 2. a) Schematic illustrating a procedure to fabricate graphene foam (GF) by using Ni foam as self-sacrifice templates and FeCl3/HCl solutions as etchants. b-d) Photographs of a graphene/Ni foam immersed in a FeCl3/HCl (1 M/1 M) solution to remove Ni (b), GF (c) and GF on a flower (d). e) Cross-sectional SEM image of as-prepared GF. (Image By SINANO)

downloadFile