Bionic condensate microdrop self-propelling (CMDSP) functional surfaces have attracted intensive interest due to their academic and commercial values, e.g., used for developing high-performance flat heat pipes for electronic cooling, energy-saving heat pump and air-conditioner heat exchangers and other devices for high-efficiency energy utilization and thermal management. Differing from gravity-driven shedding of macroscopic water drops on conventional superhydrophobic surfaces, such novel surface can realize the efficient self-propelling of small-scale condensate microdrops via their coalescence-released excess surface energy, without requiring external forces, such as gravity and steam shear force. However, it is still very challenging to endow practical heat-transfer metal surfaces with the desired CMDSP function.

A team led by Prof. GAO Xuefeng from Nanobionic Division, Suzhou Institute of Nano-Tech and Nano-Bionics, have recently made progress in revealing the mechanism of self-propelled jumping of condensate microdrops and developing a type of copper-based cerium oxide nanoparticle porous films with CMDSP function. They have demonstrated that the efficient self-propelling of small-scale condensate microdrops can be realized by the in-situ construction of bio-inspired closely packed aligned nanoneedles on material surfaces. Through theoretical modeling and analyses, they clearly revealed the mechanism that the nanostructure-induced extremely low solid-liquid interface adhesion can minimize the dissipation of coalescence-released weak surface energy so as to ensure the efficient self-jumping of merged microdrops. This work has been published, see J. Phys. Chem. Lett. 2014, 5, 2084–2088. Based on this, they developed a type of copper-based CMDSP porous films of cerium oxide nanoparticles, which can be fabricated by a facile electrochemical deposition method based on control over the preferential crystal growth of isotropic nanoparticles and the synergistic utilization of tiny hydrogen bubbles as pore-making templates. After characterizing microscopic morphology, crystal structure and chemical composition of the nanosample surface, they further explored its CMDSP performance and found that such a nanostructure film can realize the efficient self-propelling of condensate microdrop with sizes below 10 μm. The work has also been published, see Angew. Chem. Int. Ed. 2015, 54, 4876 –4879.

These works were supported by the National Basic Research Program of China, Key Research Program of the Chinese Academy of Sciences, National Natural Science Foundation of China, and the Foundation of Director of Suzhou Institute of Nano-Tech and Nano-bionics, Chinese Academy of Sciences.

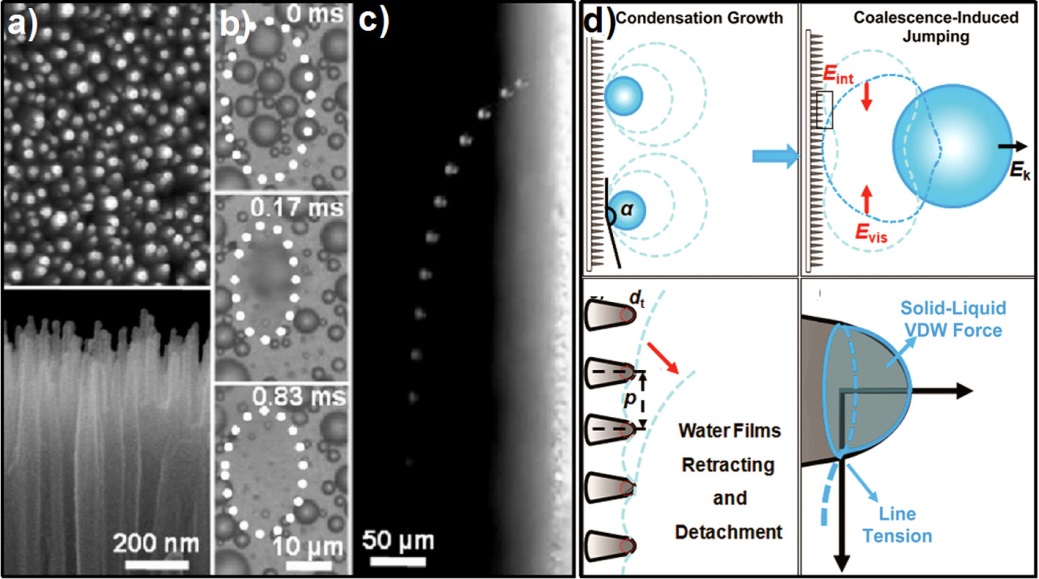

Figure 1. (a) SEM top-view (top) and side-view (bottom) of the as-synthesized closely packed nanoneedles. (b,c) Optical top-views and side-view showing coalescence-induced self-propelled jumping details of condensate microdrops on the nanosample surface. (d) Schematic diagrams for explaining the self-propelling mechanism of small-scale condensate microdrops on the top of closely packed nanoneedles.(Image by Prof. GAO Xuefeng's group)

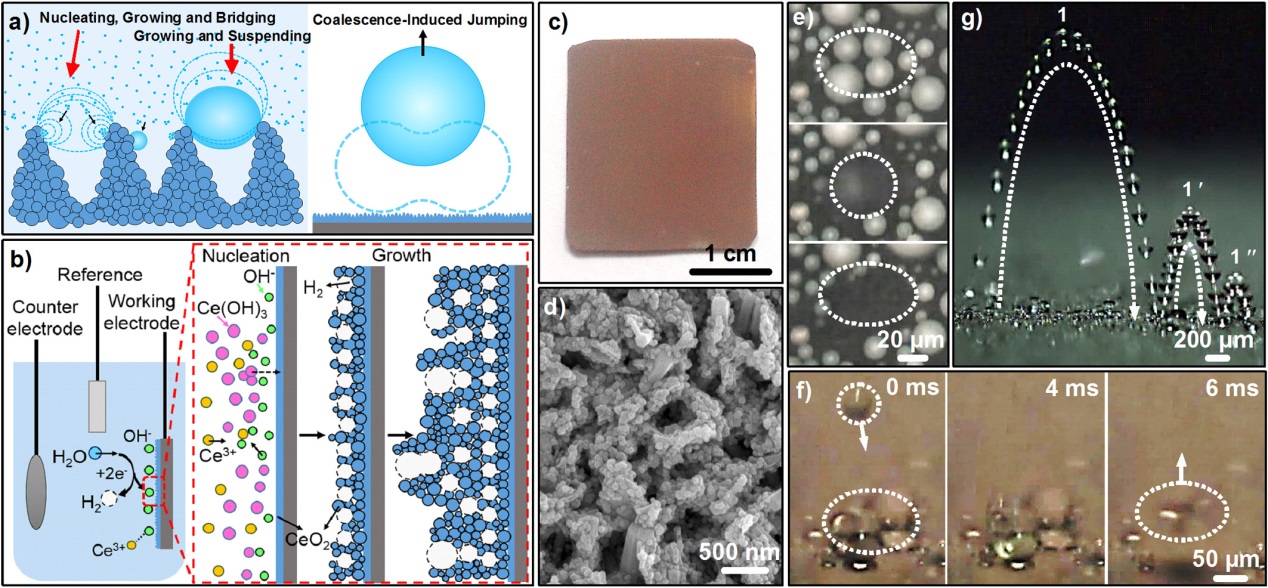

Figure 2. (a) Schematic diagrams of utilizing rugged, porous, nanoparticle films to endow copper surfaces with a condensate microdrop self-propelling function. (b) Schematics of synthesizing porous films of cerium oxide nanoparticles. (c,d) Typical optical image (c) and top-view SEM image (d) of the as-synthesized nanostructure film. (e-g) Time-lapse optical images showing different self-propelling modes of condensate microdrops by their mutual coalescence.(Image by Prof. GAO Xuefeng's group)

downloadFile