Gas separation technology has great potential in industrial separation field, benefiting for its high efficiency, low capital and operating cost, ease of operation, and environmental effectiveness. Traditional gas separation materials possessing relatively low permeability could not afford to the higher and higher industrial requirement. The gas separation membrane with high permeability and high selectivity are always pursued. Polymers of intrinsic microporosity arouse people’s great attention by their membranes’ ultra-high gas permeability. Though PIMs membranes exhibit high gas permeability, their gas selectivity are relatively low. According to Freeman’s theory, high permeability and high selectivity could be obtained by designing shape persistent polymers containing stiffer backbone coupled with interchain separation.

Recently, JIN Jian's group from Suzhou Institute of Nano-tech and Nano-bionics (SINANO),Chinese Academy of Sciences,introduced a more rigid and kinked Tr?ger’s Base (TB) structure to make new type PIMs. What’s more, solid fillers are incorporated into the obtain PIMs matrix via interfacial design strategy, aiming to making mixed matrix membrane with improved separation performance.

TB Copolymers PIMs. High purity tertrohydroxy-TB monomer is synthesized and introduced into backbone of PIM-1 via copolymerization. The copolymer are named as TBPIMs. On one hand, the more rigid and kinked TB structure enhances the rigidity of whole polymer chain. On the other hand, the alkalinity nitrogen atoms in TB unit largely increase the affinity to CO2 molecular. The two facts synergistically enhance ideal selectivity of CO2/N2, CO2/CH4, O2/N2 gas pairs. (Poly. Chem. 2014, 5, 2793-2800)

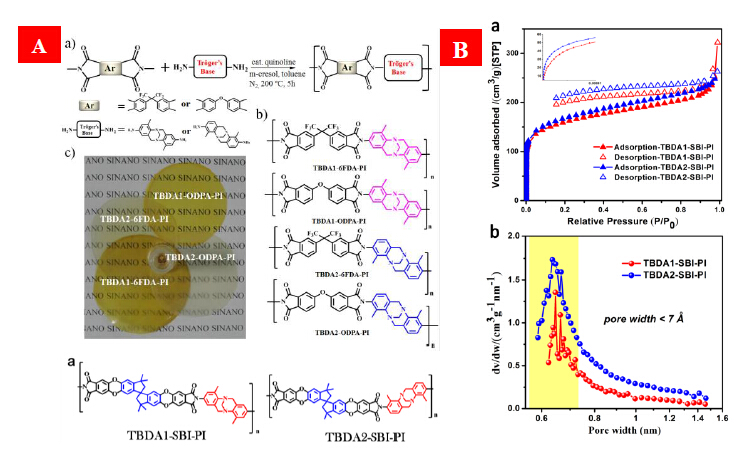

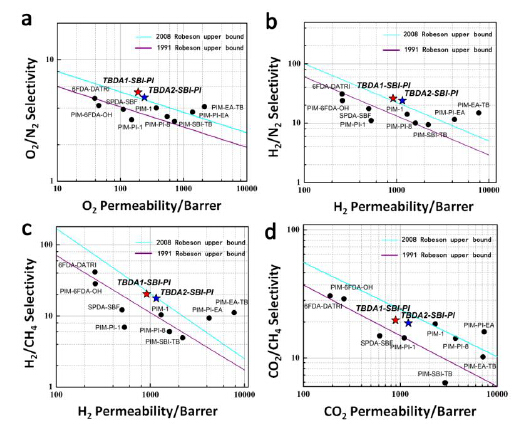

Common polyimides possess high gas selectivity but very low permeability. As shown in Figure 1, TB derived diamines with high purity are synthesized and TB polyimides were obtained via high temperature polycondensation. The highest BET surface area of the polyimdes is up to 300 m2/g. The gas permeation testing reveals that the separation performance of TB polyimides are largely improved compared with common polyimide. (ACS Macro Letters, 2014, 3, 597-601) Furthermore, new rigid and kinked dianhydride (SBI) is synthesized. By polycondensation reaction with TB diamines, microporous polyimides contained two parts of rigid chain segments are obtained. The obtained polyimides possess high BET surface area up to 600m2/g. The surface area is about twice of single rigid chain segment polyimde. Gas permeation test reveals that the permeability of H2 and CO2 is up to 1000 barrer with a high gas selectivity. The comprehensive separation performance surpass the 2008 Robeson upper bound (Figure 2). (Macromolecules, 2014, 47, 7477-7483)

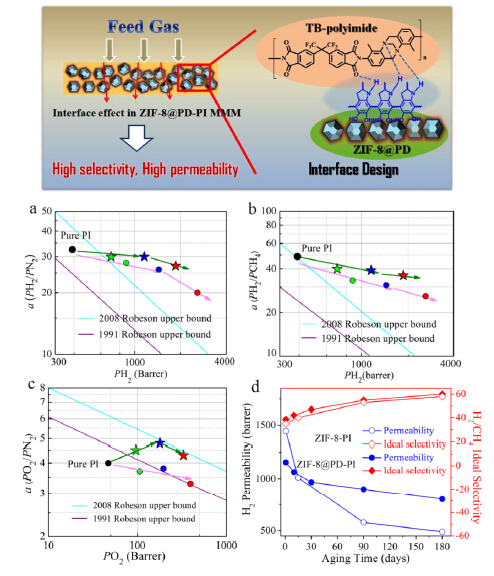

TB polyimide/MOF mixed matrix membrane (MMM). MOFs with definitive pore size and high porosity possess good gas sieving properties. However, there have problems in MOF dispersion in polymer matrix and compatibility issue between MOF and polymer matrx. MOF particle is coated with an ultra-thin polymer layer, which avoids MOF crystal and polymer matrix direct contact. What’s more, the interfacial interaction is further enhanced by hydrogen bond forming between coated MOF and polymer matrix (Figure 3). The designed MMMs exhibit excellent comprehensive gas performance largely surpassing the 2008 Robeson upper bound. Moreover, the designed MMMs have very good anti-aging performance. The permeability decreasing rate is much lower than that of MMM contained uncoated MOF. (Adv. Mater. DOI: 10.1002/adma.201504982).

Figure 1. Polyimide of intrinsic microporosity containing Troger’s base synthetic routes, chemical structure, membrane optic photo and Nitrogen adsorption/desorption curve.(Image by JIN Jian's Group)

Figure 2. Gas separation performance of polyimide of intrinsic microporosity containing Troger’s base.(Image by JIN Jian's Group)

Figure 3. Interfacial design of Mixed matrix membrane and relative gas separation performance.(Image by JIN Jian's Group)

Contact information:Prof. JIN Jian

Suzhou Institute of Nano-Tech and Nano-Bionics ,Chinese Academy of Science

Suzhou, Jiangsu 215123, China.

E-mail: jjin2009@sinano.ac.cn

downloadFile