Oil-related activities during modern industrialization promote social development and people’s life quality, but simultaneously generate tremendous amount of oily wastewater, which kills aquatic creatures, damages people’s health, and further aggravates the shortage crisis of drinkable freshwater in a wide range of ways. Oil/water separation has become a worldwide subject. However, collecting or separating viscous oils from real oily wastewater is still a tough work, especially for oil spill. Core reason for this is the high viscosity and adhesive property of crude oil, which always brings about serious pollution to base materials and cause invalidation of all instruments. Sustainable and fouling-free solutions for separating viscous oils and cleaning up oil spill are always worldwide challenges.

Recently, Prof. JIN Jian’s group, at Suzhou Institute of Nano-tech and Nano-bionics, Chinese Academy of Sciences, developed a novel robust polyionized hydrogel coating/membrane that possesses a superanti-crude-oil-adhesion property. The polyionized hydrogel coating/membrane composed of sodium polyacrylate-grafted polyvinylidene fluoride (PAAS-g-PVDF) is fabricated by a one-step alkaline-induced phase inversion process (Figure 1). The PAAS-g-PVDF exhibits an underwater ultralow-oil-adhesive superoleophobicity to viscous oils such as silicone oil, heavy diesel oil, crude oil and even heavy oil with underwater oil contact angles all above 165° and nearly zero underwater oil adhesion force. This work has been published in Adv. Mater. DOI:10.1002/adma.20160417.

Figure 1. Schematic showing the formation of PAAS-g-PVDF coating/membrane.(Image by JIN Jian's group)

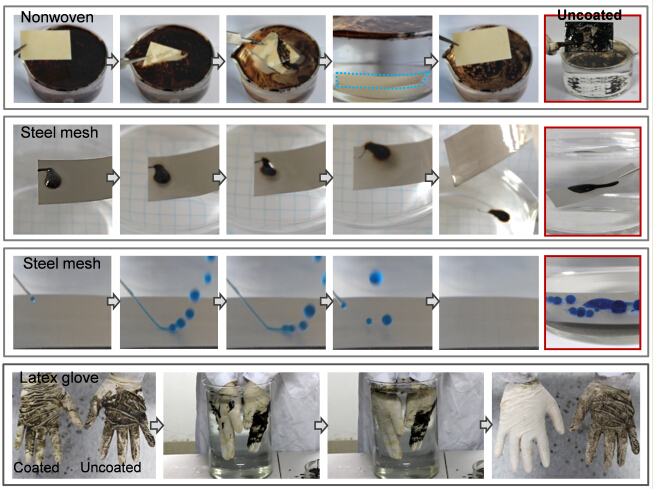

The molecular dynamic simulation result indicates the ionized polymer PAAS-g-PVDF possesses a stronger hydration capability and more stable hydration layer than unionized polymer. The structural analysis indicates the ionized polymer PAAS-g-PVDF can combine more water molecules than unionized polymer, and the densely distributed hydrogen bond network also stabilizes the hydration layer. This tightly bound hydration layer forms a physical and energetic barrier to prevent the adhesion and fouling of oil molecules. As shown in Figure 2, the PAAS-g-PVDF coating on various materials (such as metal mesh, foam, nonwoven, and plastic, etc.) is free of viscous oil adhesion and are self-cleaning from viscous oils in aqueous environment.

Figure 2. Underwater anti-oil-adhesion and self-cleaning property of PAAS-g-PVDF coatings.(Image by JIN Jian's group)

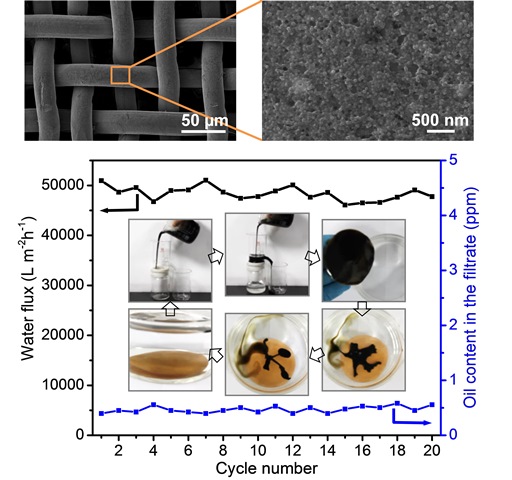

Meanwhile, the membrane made of PAAS-g-PVDF-coated copper mesh can effectively separate viscous oily water composed of crude oil (viscosity: 21 mPa s-1) driven only by gravity (Figure 3), with an extremely high water flux up to 50000 L m-2 h-1 and very high oil rejection (oil content in the filtrate water after one-time separation is as low as 0.5 ppm). This PAAS-g-PVDF-coated copper mesh is self-cleaning from crude oil in water and easily recycled for long-term use. The superior anti-viscous-oil-adhesion property and easily scaled-up fabrication process of PAAS-g-PVDF coating/membrane show great potential for anti-crude-oil-fouling clothes, instruments, ships, etc. and for purifying oily wastewater composed of various oils. Further investigation of the ionized hydrogel polymer coating can provide a revolutionary strategy for fouling-free treatment of offshore oil spills.

Figure 3. Separation of crude oil/water mixture using a PAAS-g-PVDF-coated copper mesh.(Image by JIN Jian's group)

Contact information: Prof. JIN Jian

Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Science

Suzhou, Jiangsu 215123, China.

E-mail: jjin2009@sinano.ac.cn

downloadFile