Microbes are widely used in the chemical, food, pharmaceutical, and health care industries as well as new industries such as environmental remediation, green chemistry, sustainable manufacturing, biomass energy and resources, and low-carbon biodiesel. Improvement in the microbial production strains offers great opportunity for elevated profits and sustainability of relevant industries without significant capital outlay. Shake flasks and tubes account for 90% or more of all microbe culture experiments. However, current flask culture techniques require large numbers of flasks, bulky shaking beds, large fluid volume, intensive human labor and expensive equipment, and thus cause poor screening efficiency.

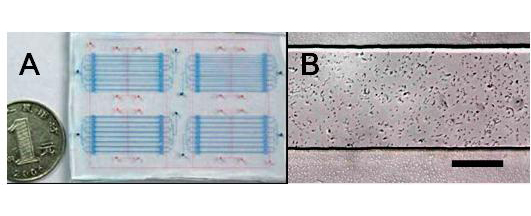

Recently, Dr. GAN Mingzhe from the i-LAB of Suzhou Institute of Nano-Tech and Nano-Bionics (SINANO), CAS, invented a novel scalable multi-channel microfluidic chip for bacterial suspension culture (Figure 1A). In this device, culture media in 32 parallel and identical culture chamber loops are driven by a series of micropumps formed with a single set of control channels. The culture media indifferent culture loops are demonstrated to cycle at the same speed, which ensures identical growth environments in all culture loops. Suspended cultivations of microbial strains such as E.coli (Figure 1B), Bacillus subtilis, Pseudomonas stutzeri and Zymomonas mobilis are carried out to demonstrate general applicability of the chip for microbial culture. The simple chip design and low-cost fabrication allow for an efficient microbial suspension culture. This work has been published on Lab on a chip [link to the publisher article].

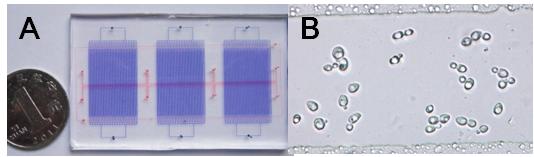

On the basis of this work, Dr. GAN and colleagues developed a second-generation microbial culture chip (Figure 2A). A high degree of integration of 120 culture chambers (50 nL each) in a 7.5 cm× 5 cm chip is achieved. A faster circulating flow rate enables the suspension culture of various microbial strains including bacteria as well as yeast (Figure 2B). Simpler fabrication process allows for future low-cost industrial chip production. This work has been recently published on small [link to the article on publisher website].

Both works are the parts of project “microbial screening and analysis system”. The objective of the project is to develop an integrated microfluidic system for microbial screening and optimization, which could greatly speed up strain selection processes in microbial industry. Current the research is focusing on the development of rapid micro-analysis technology for microbial metabolites.

This work is supported by the Hundred Talents Program of Chinese Academy of Sciences and the Knowledge Innovation Program of the Chinese Academy of Sciences.

|

| Fugure 1. (A) First generation suspension culture chip with 32 culture loops. (B)Micrograph of the suspension culture of E. coli on chip. |

|

| Figure 2. (A) Second generation suspension culture chip integrated with 120 culture loops. (B) Micrograph of the suspension culture of yeast on chip. |