Wastewater containing emulsified oil/water mixtures is generated in diverse industrial technologies, such as the petrochemical, food, textile, leather, steel, and metal finishing industries, the direct discharge of which will bring about harm to the environment and people’s health. The separation of emulsified oil/water mixtures is always difficult and challenging as they are prone to be present in multiple forms under differing conditions. Traditional techniques for oil/water separation such as air flotation, gravity separation combined with skimming, oil-absorbing materials, coagulation, and flocculation are limited by low separation efficiency, energy-cost, and complex separation instruments, etc. and are not effective for separating tiny oil droplets from water, making further treatment necessary. Polymer-oriented filtration membranes such as for ultrafiltration (UF) have been successfully applied for the separation of surfactant-stabilized oil-in-water emulsions driven by external pressure. But the most serious limitation of filtration membranes is the low flux and quick decline of permeation due to oil adsorption and/or pore plugging by oil droplets, which lead to severe fouling issues and are hard to clean. Owing to the different interfacial effects of oil and water, utilizing the wetting behavior of solid surfaces to design an oil/water separation process has been considered effective.

Recently, Dr. Jin jian’s research group at Suzhou Institute of Nano-Tech & Nano-Bionics, Chinese Academy of Sciences(SINANO), reported a series of special wetting membranes with superhydrophobic-superoleophilic or superhydrophilic-superoleophobic properties which could separate water-in-oil or oil-in-water emulsion with very high penetration flux and separation efficiency.

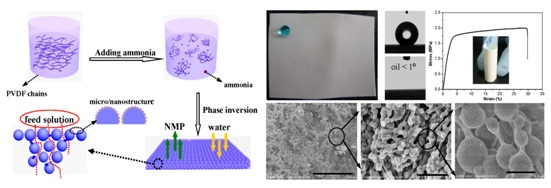

PVDF is one of the most used materials for forming microfiltration and ultrafi ltration membranes due to its outstanding properties, such as thermal stability, chemical resistance, and high mechanical strength. PVDF membranes are usually fabricated in bulk via a phase-inversion process which could result in porous polymer films. Different from common-phase inversion, a modified process was used in our work as shown in Figure 1, where ammonia water was added as an inert solvent additive into the polymer solution to induce localized microphase separation and causes uniformly skinless and composed of spherical particles (Figure 1). A superhydrophobic-superoleophilic PVDF membrane is thus produced. The membrane exhibited high water flux and separation efficiency for micro/nano water-in-oil emulsion which is two orders compare to traditional separation membranes (Adv. Mater. 2013, 25, 2071).

Figure 1. Formation and structure of the superhydrophobic-superoleophilic PVDF membranes.(Image By SINANO)

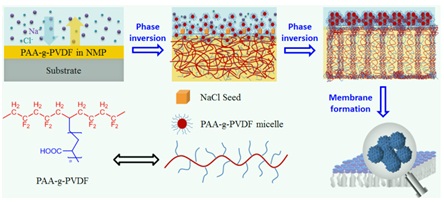

In addition, a series of superhydrophilic and underwater superoleophobic poly(acrylic acid) grafted PVDF(PAA-g-PVDF) membrane via a salt-induced phase inversion. Completely different from the general approach of adding salts (such as LiClO4, LiCl) as pore-forming additive into PVDF solution to change the pore structure of PVDF membrane, thus to improve the membrane permeability. The salt (NaCl) with nearly saturated concentration is added into the coagulation bath to function as nucleates at the interface of two liquids during solvent exchange to induce the assembly of PAA-g-PVDF micelles around them. This salt-induced micelle assembly at interface gives rise to a micro/nanoscale hierarchical structure on membrane surface to endow the membrane a superhydrophilic and underwater superoleophobic property. As a consequence, the membrane can separate both surfactant-free and surfactant-stabilized oil-in-water emulsions under a small applied pressure (0.1 bar) or solely driven by gravity, with high separation efficiency (water purity in filtrate after one-time separation > 99.99 wt %) and high flux (Figure 2). The outstanding performance of the membrane for oil-in-water emulsion separation and its industrially processable preparation process indicate its great potential for practical application (Angew: Chem. Int. Ed. 2013, DOI: anie. 201308183.)

Figure 2. Schematic illustration salt-induced membrane phase inversion process.(Image By SINANO)

In principle, at the center of oil–water separation is an interfacial problem, designing materials with special wettability, has been concerned to be an effective and facile way to realize oil-water separation by either filtration or absorption of oil or water from mixtures selectively. Until now, few reports have been given on fabricating membranes which can thoroughly separate oil from water to directly meet the requirement of the stringent standards for wastewater discharging. In our group, we fabricated a novel zwitterionic polyelectrolyte brush PMAPS via a surface-initiated atom transfer radical polymerization process (Figure 3) and the obtained membrane could thoroughly separating dispersed oil from water with an oil content after one-time separation less than 10 ppm (J. Mater. Chem. A, 2013, 1, 5758).

Figure 3. Illustration of the grafting of polyelectrolyte brush on PVDF membrane.(Image By SINANO)

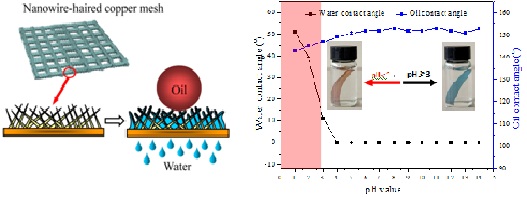

However, traditional approaches solely make use of polymer and/or polymeric coatings on a mesh matrix with limited selectable options and weaknesses on performance to a certain extent in consideration of practical application, especially on stability under severe conditions, long-term preservation for repeated use. Jin’s group extended the special wetting theory to inorganic material by fabricating novel all-inorganic membrane with superhydrophilicity and underwater ultralow adhesive superoleophobicity for oil/water separation (Figure 4). The nanowire-haired membrane was prepared by surface oxidation of a copper mesh in an alkaline aqueous solution with (NH4 )2S2O8 and the membrane composed of a Cu(OH)2 nanowire-haired copper mesh can effectively separate both immiscible oil/water mixtures and oil-in-water emulsions, solely driven by gravity, with extremely high separation efficiency and residual oil in the filtrate after only one separation was lower than 30 ppm, which meets the requirement of the stringent standards for wastewater discharge. Most importantly, the membrane exhibits a high separation capacity, which can separate ten liters of an oil/water mixture continuously without a decrease in flux, and excellent antifouling properties and chemical stability. The excellent capability for oil/water separation and the low cost and easily scaled up preparation process of the membrane indicate its great potential for practical application (Adv. Mater. 2013, 25, 4192).

Figure 4. Illustration of oil wetting on nanowire-haired membrane and the pH stability of membranes.(Image By SINANO)

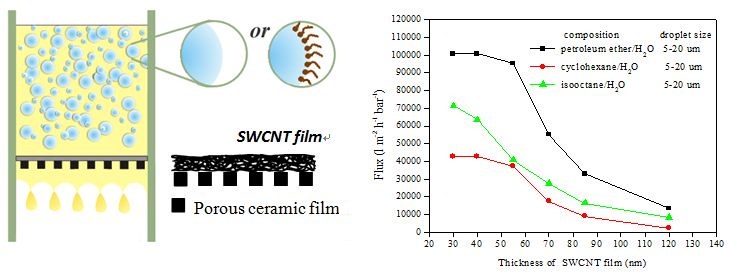

The most serious limitation of pressure-driven filtration membranes f is low flux and a quick decline of permeation due to surfactant adsorption and/or pore plugging by oil droplets. To further improve the permeation properties. Jin’s group reported an alternative to polymer membranes based on ultrathin single-walled carbon nanotube (SWCNT) network films for the ultrafast separation of emulsified oil/water mixtures by simulating the interpenetrated polymer network structure of polymer chains. Free-standing SWCNT network films were prepared by first vacuum-filtering a SWCNT suspension through a cellulose ester (MCE) filter membrane and then releasing it from the filter (Figure 5). The films with a tunable thickness of the tens of nanometer scale can effectively separate both micrometer and nanometer-sized surfactant-free and surfactant-stabilized water-in-oil emulsions with fluxes up to 100 000 L m-2 h-1 bar-1, which is 2–3 orders of magnitude higher than commercial filtration membranes with a similar separation performance and with a high separation efficiency which is larger than 99.95 wt% (Adv. Mater. 2013, 25, 2422) .

Figure 5. Schematic illustration of emulsion separation process and flux value of the SWNT membranes.(Image By SINANO)

The series of researches focused on the design and controllable fabrication of novel interfacial nanomaterials with high performances, especially on preparation and characterization of intelligent-responsive porous membranes for oil-water and emulsion separation which gave a new idea on designing and fabricating separation membranes.

These works were supported by the National Basic Research Program of China (grant No. 2013CB933000 and 2010CB934700), the National Natural Science Foundation of China (grant No. 21004076), and the Key Development Project of Chinese Academy of Sciences (grant No. KJZD-EW-M01-3).