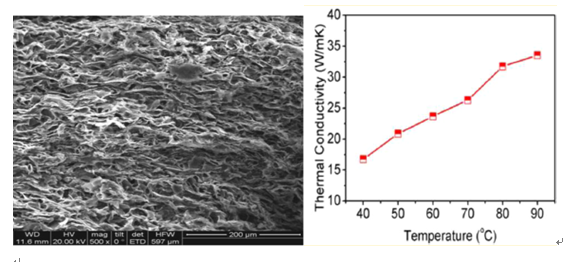

Thermal conductivity composite materials have a broad application in electronic devices, optoelectronic devices, and consumer electronics. Enhanced thermal conductivities of the composites over the neat polymers have been achieved by the commonly used conductive fillers, such as metal powder, metal oxides, and metal nitrides. However, the improvements are very limited, because of thelarge thermal resistances that exist in the interfacial regions of fillers and polymer. Suzhou Graphene Nanotech. Co., Ltd., cooperating with Institute of Suzhou Nanotech., CAS has successfully to prepare high thermal conductivity composite materials using aligned graphene layers as the filler because of their extraordinarily high in-plane thermal conductivity, and large specific surface area. The composite exhibits a strong anisotropic alignment of graphene layers between parallel and perpendicular directions through the fabrication of the vertically aligned and densely packed graphene layers in the epoxy matrix. The ultrahigh thermal conductivity of composite up to 33 W/(mK) in the parallel direction has been achieved, which is so far the highest thermal conductivities for graphene-based polymer composites. The value is much higher than those of the epoxy-based composites containing other fillers, and it can exceed some common alloys, such as stainless steel (16.7 W/(mK)) and bronze (26.2 W/(mK)). This work has been published on Chem.Mater. 26,4459 (2014) The work was supported by National Natural Science Foundation of China, and Ministry of National Science and Technology Projects of China. The project also got assistance from the Nanofabrication Facility and Platform of Characterization & Test of SINANO.

Figure.SEM image of the structure of the composite and its thermal conductivity. |