Piezoresistive sensors, transducing pressure message to resistance signal, have been rapidly developed and widely used for their advantages in high sensitivity, fast response, feasible fabrication, low cost, and easy signal collection. However, as the core part of sensors, the piezoresistive materials always show temperature drift caused by the temperature-dependent electrical resistances. So, the temperature compensation has to be involved in order to determine the stress being measured accurately. Even so, the temperature compensation systems have to be calibrated frequently due to the newly-exploit and volatile application environments, making the measurements more complex and applicably restricted. Hence, self-temperature-compensated sensors are highly desirable in direct and precise measurement. The most feasible solution is developing hybrid sensing materials with a low/nearly-zero temperature coefficient resistivity (TCR) by offsetting the positive and negative temperature-dependence of electric resistance.

A team led by Prof. ZHANG Xuetong from Advanced materials Division, Suzhou Institute of Nano-Tech and Nano-Bionics, developed an Incipient Network Conformal Growth (INCG) technology, via which they produced polypyrrole/silver coaxial nanowire hybrid aero-sponges prepared for self-temperature-compensated stress sensing. The work was recently published in ACS Nano (doi: 10.1021/acsnano.5b00626).

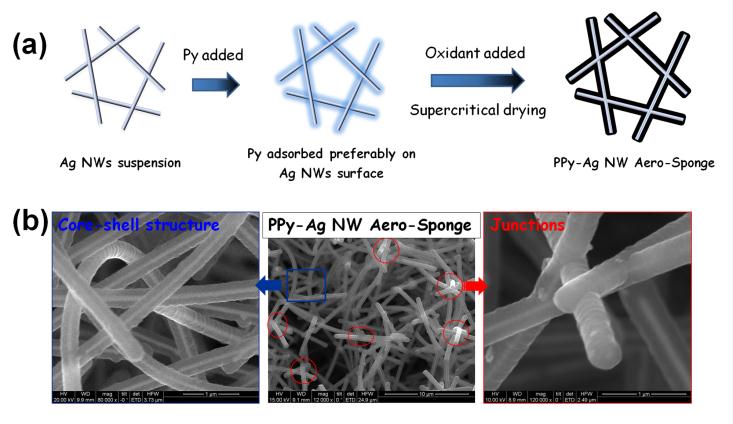

To obtain ideal sensing materials with nearly zero temperature coefficient resistance (TCR) for self-temperature-compensated pressure sensors, the researchers proposed an Incipient Network Conformal Growth (INCG) technology: the nanoparticles (NPs) are first dispersed in solvent to form an incipient network, another component is then introduced to coat the incipient network conformally via wet chemical route. The conformal coatings not only endow NPs with high stability but also offer them additional structural elasticity, meeting requirements for future generations of portable, compressive and flexible devices.

The resultant polypyrrole/silver coaxial nanowire hybrid aero-sponges prepared via INCG tech. have been processed into a piezoresistive sensor with highly sensing stability (low TCR 0.86 *10-3 /οC), sensitivity (0.33 kPa-1), short response time (1 ms), minimum detectable pressure (4.93 Pa) after suffering repeated stimuli, temperature change and electric heating. Moreover, a stress-triggered Joule heater can be also fabricated mainly by the PPy-Ag NW hybrid aero-sponges with a nearly zero temperature coefficient.

This work was financially supported by the National Natural Science Foundation of China, the Natural Science Foundation of Jiangsu Province, the 100 Talents program of the Chinese Academy of Science, the Postdoctoral Research Foundation of Jiangsu Province.

Figure 1. Schematic representation of the formation of PPy-Ag NW aero-sponges. (a) Schematic illustration for the fabrication process of PPy-Ag NW aero-sponges. (b) SEM images of Ag NW-PPy aero-sponges with red circles highlighting the in-situ welded junctions and enlargements of structural details.(Image by Prof. ZHANG Xuetong's group)

Figure 2. The properties of PPy-Ag NW hybrid aero-sponges in stress sensing. (a) The relative electric resistance changes - temperature (ΔR/R-T) curves for Ag NWs, PPy-Ag NW membrane deposited by nanocable suspension and PPy-Ag NW hybrid aero-sponge, respectively. (b) Schematic illustration of how to prepare a stress sensor with PPy-Ag NW aero-sponge, copper sheets and metal wires. (c) SEM images of PPy-Ag NW aero-sponge with 0, 50 and 80 % compression. (d) Multiple-cycles electric resistance tests of repeated loading and unloading pressure with different values with 1 V voltage input. (e) Reliability test of PPy-Ag NW hybrid aero-sponge under repeated loading and unloading pressure at different values with partial enlarged details in insets. (f) The relative electric resistance changes-compressive pressure (ΔR/R-p) curves for PPy-Ag NW aero-sponge performed at 25 and 15 оC, respectively. (g) Electric resistance response of nearly-zero temperature coefficient sensor at different strain by introducing a series of persistent compressive pressure. .(Image by Prof. ZHANG Xuetong's group)