Constructing macroscopical 3D graphene architectures from each single graphene sheets is one of the effective ways to push practical applications of graphene. The properties of 3D graphene are intensively governed by their construction structures. Thus a novel approach to efficiently control pore size and shape of 3D graphene is certainly needed. Meanwhile, controllable fabrication of 3D graphene architectures with precise dimension and shape not only modulate the properties of 3D graphene to meet different demands for various applications, but also offer an insightful investigation on the functional mechanism of 3D graphene at different levels.

Prof. CHENG Guosheng’s group with Key Laboratory for Nano-Bio Interface, Chinese Academy of Sciences, also Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences, has reported some achievements on cellular effects function by graphene based on the successfully fabrication of 3D graphene neuroscaffold. (Scientific Reports, 2013, 3, 1604) The topographical structures of the 3D graphene can affect the material-cell interaction, leading to disparate effects on lipopolysaccharide-induced neuroinflammation, showing the ability of anti-inflammation against external insults. (Biomaterials, 2014, 35, 6930;Biomaterials, 2013,34, 6402). Researchers also explored how conditioned mediums, produced from microglia grown in the 3D-G culturing systems, manipulated NSC migration by addressing the signal pathway and molecular mechanism of NSC migration.

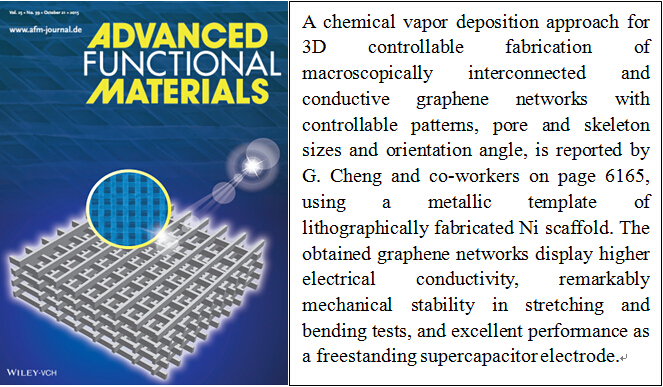

Very recently, Dr. XIAO Miao and Dr. KONG Tao from Cheng’s lab successfully accomplished controllable fabrication of 3D graphene to construct well-defined neuroscaffolds mimicking the microenvironment in vivo. Inside front cover of Advanced Functional Materials reported this new progress. (Advanced Functional Materials, 2015, 25, 6165) Taking advantage of micro-fabrication, researchers prepared 3D graphene with specific shape, pore and skeleton size via CVD, using 3D Ni scaffolds of lithographically fabricated. Specifically, the pore and skeleton sizes of uniform 3D-CG architectures can be regulated from 10 μm to 50 μm and the angle of the interconnected skeleton can be designed as 45° and 90°. This customer-made 3D graphene not only provides an opportunity for constructing application-driven neuroscaffolds, but also shows great potentials in flexible electrodes and supercapacitor.

These works were financially supported by the Ministry of Science and Technology of China and National Natural Science Foundation of China. Cheng’s group is grateful for the professional services by Platforms of Characterization & Test and Nanofabrication Facility at Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences.

Inside cover of Advanced Functional Materials and illustration

Contact information:Prof.CHENG Guosheng

Suzhou Institute of Nano Tech and Nano Bionics ,Chinese Academy of Science

Suzhou,Jiangsu 215125,China.

E-mail:gscheng2006@sinano.ac.cn