Oily wastewaters containing either a large amount or a trace of oil contaminants are being generated in many industrial processes, and the direct discharge of these wastewaters will cause a serious environmental issue. The pressure-driven filtration membranes have been proven to be an effective and simple technology for the separation of various oil/water emulsions with acceptable discharge quality. As most of the membrane-forming polymers are intrinsically hydrophobic and oleophilic, the resulting polymeric membranes with relatively smooth surfaces are prone to be oleophilic and easy to fouling. Traditional polymeric filtration membranes are usually prepared via a phase inversion process, either solvent-induced or thermal-induced phase inversion. To address the fouling issue, polymeric membranes with improved hydrophilicity through either surface modification, polymer grafting, or blending with hydrophilic components have been fabricated. However, these approaches always need either chemical reaction processes or complicated post-treatments which might give rise to secondary pollutions.

Recently, Prof. JIN Jian’s research group at Suzhou Institute of Nano-Tech & Nano-Bionics, Chinese Academy of Sciences (SINANO), firstly proposed an alkaline-induced phase inversion process is to design superhydrophilic and underwater superoleophobic polyacrylonitrile (PAN) ultrafiltration membrane which could effectively separate oil-in-H2O emulsions with a high flux and an extremely high rejection while the oil residual in filtrate after one-time separation is lower than 10 ppm [Figure 1]. Also, the PAN membrane showed ultralow oil adhesion and antifouling properties.

Figure 1. Schematic illustration of alkaline-induced phase separation process.(Image by JIN Jian's group)

PAN is a well-known membrane-forming polymer material and widely used in ultrafiltration, nanofiltration, reverse osmosis, and pervaporation because of its good chemical and thermal stability and anti-solvent property. However, due to the intrinsic nature of hydrophobicity and oleophilicity. PAN filtration membrane is seldom to be used for effective oil/water separation. During the alkaline-induced phase inversion process, NaOH is added as an additive into coagulation bath to induce the formation of superwetting PAN membrane. On the one hand, NaOH as an additive inspires the localized micro phase separation of PAN and leads to the formation of rough structure on membrane surface which enhances the wetting property of PAN membrane; On the other hand, the existence of NaOH induces the in-situ hydrolysis of -CN groups to -COOH groups, which is a critical step to introduce a hydrophilic component in PAN chain and to finally achieve superhydrophilicity.

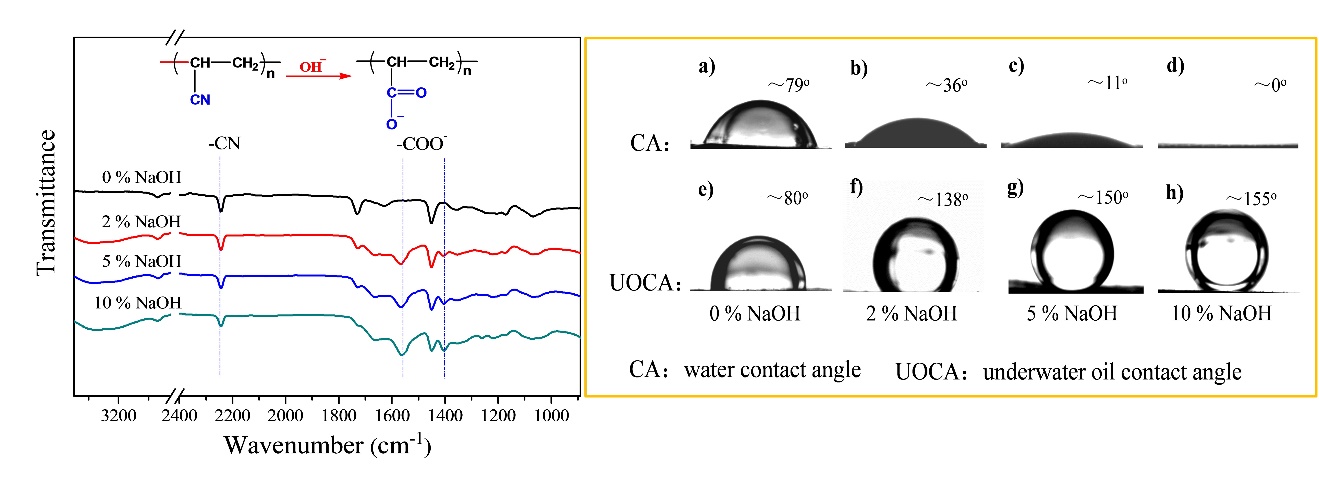

Figure 2. In-situ hydrolysis of PAN and changes of surface wetting behavior.(Image by JIN Jian's group)

By using the alkaline-induced phase separation process, the surface wetting behaviors changed a lot with addition of NaOH in coagulating bath. The PAN membrane prepared from the coagulation bath without NaOH showed the CA of 79° and UOCA of 80°, which revealed the intrinsic wetting property. The PAN changed to superdydrophilic and underwater superoleophobic property in the case of 10% NaOH with CA of 0° and UOCA of >150° [Figure 2]. It indicates that the alkaline-induced in-situ hydrolysis of -CN to -COOH group during the PAN membrane formation and the micro/nano hierarchical structures on PAN membrane surface contribute together to the superwetting property of PAN membrane.

Figure 3. Oil-in-H2O emulsion separation results of the PAN membrane.(Image by JIN Jian's group)

Owing to the superwetting property, the novel PAN membranes can separate both surfactant-free and surfactant-stabilized emulsions and exhibit high fluxes more than 2000 L/m2•h under 1 bar trans-membrane pressure which is 2-3 times higher than those of traditional polymer membranes. None droplets are observed in the image of collected filtrate after filtration compared to feed solution with oil droplets of 5-30 mm [Figure 3]. This new PAN membrane has a great potential for treating oily wastewater.

Reference:

Alkaline-induced Superwetting Polyacrylonitrile Membranes for High-efficient Oil/water Separation with Ultra-low Oil-adhesion.

Contact information:Prof. JIN Jian

Suzhou Institute of Nano-Tech and Nano-Bionics ,Chinese Academy of Science

Suzhou, Jiangsu 215123, China.

E-mail: jjin2009@sinano.ac.cn